Candy is one of the most popular foods. Candy products include chewing gum, sweets, and chocolate. The global confectionery industry has grown every year except during the COVID-19 outbreak, so competition among manufacturers has increased dramatically. Humidity is a huge challenge for both the small-sized home candy industry and the large-sized industry. Because the main ingredient sugar in confectionery is hygroscopic, and it can easily absorb water from the environment. As a result, if not properly preserved, candy can absorb moisture from the air and become sticky, and may even become moldy.

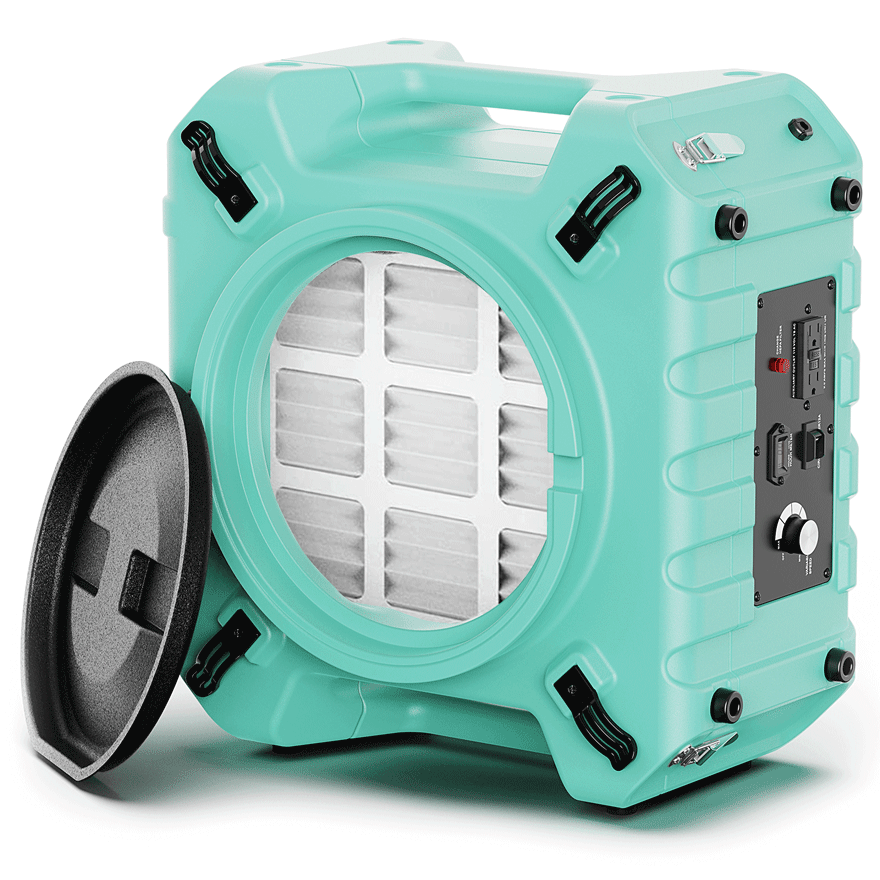

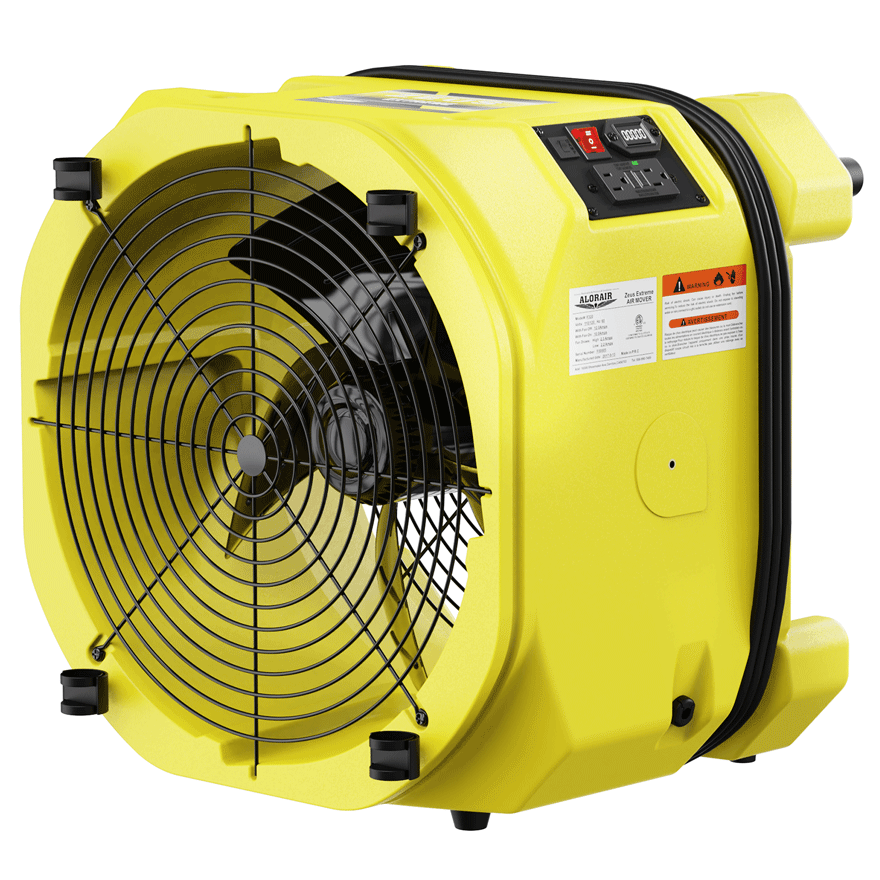

The best way to protect candy from moisture is to install a proper dehumidifier. Dehumidified products such as cookies, chocolate, gum, candy, candy, sugar, cocoa, sugar-coated pills or drops, cookies, popcorn, jellies can maintain quality and extend shelf life. Therefore, the dehumidifier should be an integral part of the candy production process.

In the confectionery industry production process, the application rate of dehumidifiers is very high. For example, candy storage, transportation, unloading silo, packaging, coating, and other approaches need dehumidification. In addition, dehumidification is also essential in other steps such as delivery to the customer. Failure to maintain humidity in one of these steps can have serious consequences. Therefore, each step must maintain a certain level of moisture.

What could go wrong if the humidity is not controlled? First, high humidity can affect the quality and shelf life of confectionery products. If the confectionery products are exposed to damp air during production, they may lose their desired shape. They can become sticky and even moldy due to the moisture in the air. In addition, the high humidity may clog machines and pipes, which can lengthen production time and increase production costs.

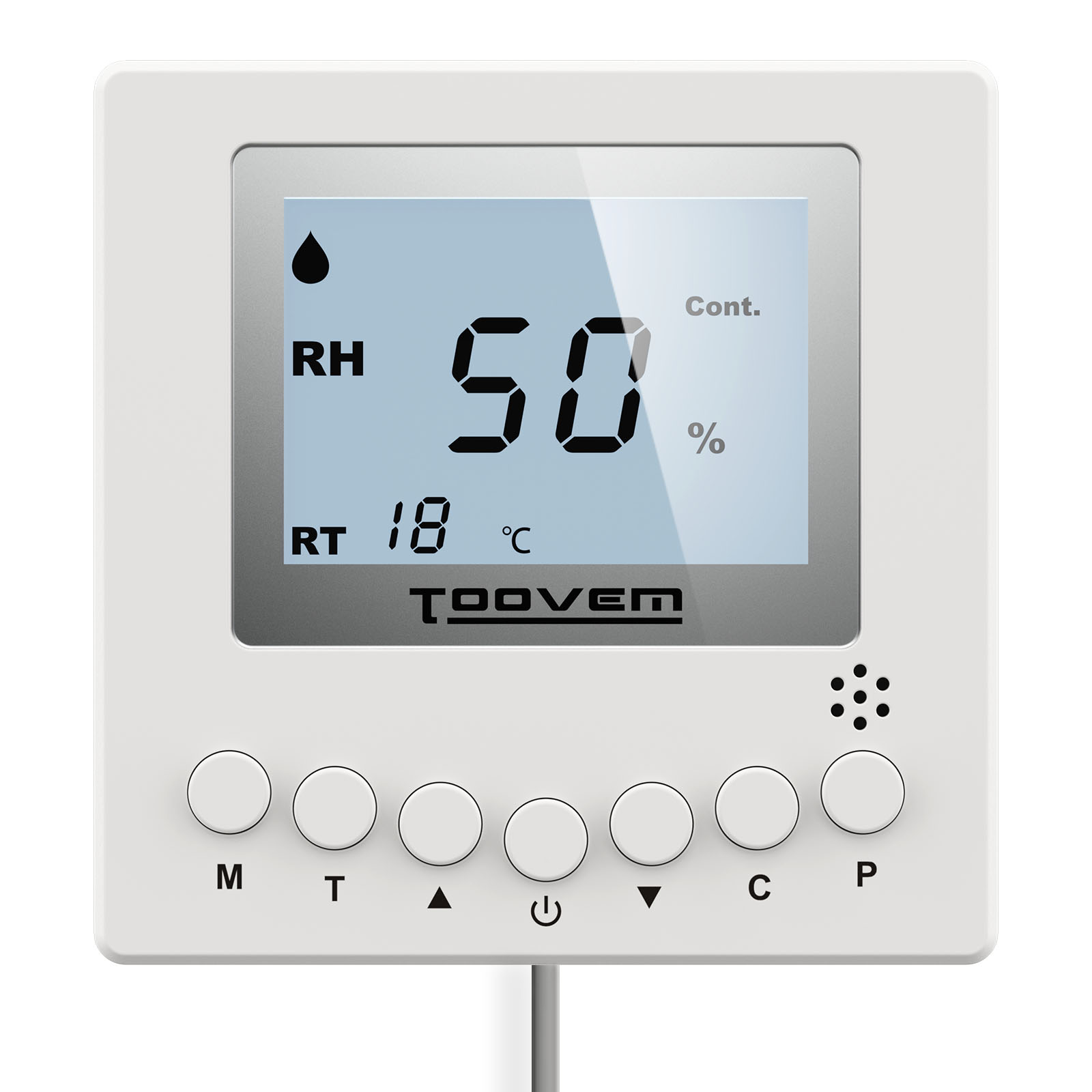

The best way to protect the quality of products is to create an ideal environmental condition. Raw materials should be stored in dry air, and production, storage, and transportation should be carried out under controlled environmental conditions. During the whole production process, air humidity must be continuously monitored and adjusted from raw materials to final products to ensure quality. Our dehumidifiers are designed to operate efficiently in every season of the year. We provide our customers with customized dehumidification solutions for all production areas. Whether it is the storage of raw materials or final products, silos or production facilities, warehouses, or transportation of dry, these dehumidifiers can help control the humidity, which can help you save production time and cost.

.jpg)

.jpg)

.jpg)

.HDi90.png)

.HD90.png)

-Duct.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-.jpg)

.jpg)

.jpg)

.jpg)

Exclusive offers

promotions

Exclusive offers

promotions