All sweet things should be completely stuck in the mouth. However, moisture will have a destructive effect on the way, destroy the texture, and make the confectionery moist and visually unattractive. The reason for all this is because candies-chocolate, hard candies, chewing gum, bubble gum, etc. are rich in sugar and therefore hygroscopic. When the humidity is high, the candy item regains moisture and becomes sticky and prone to mold.

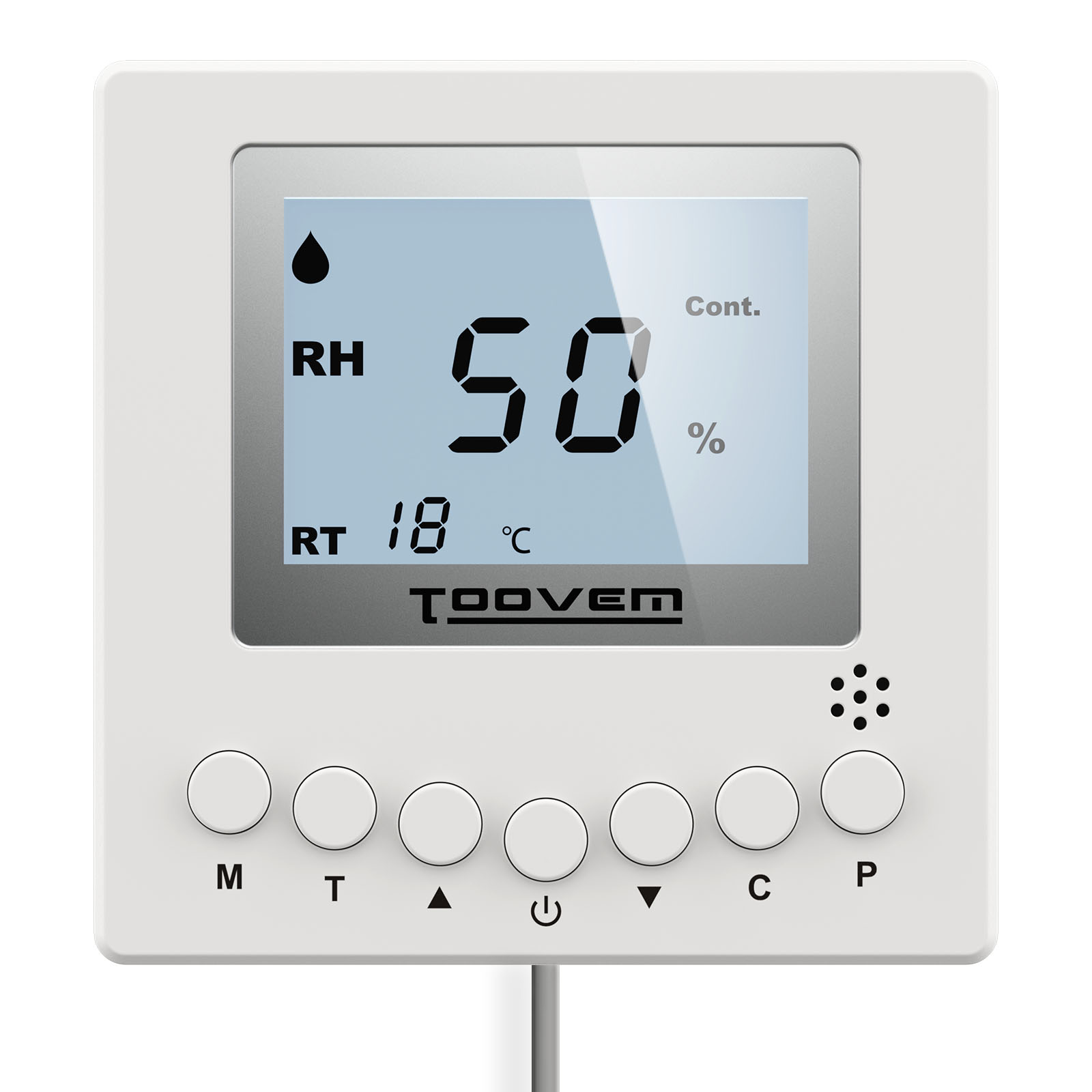

The temperature and humidity requirements of the production workshop of the candy processing factory: the temperature is 22~26 degrees, which is the best temperature for machine operation and the most comfortable temperature for workers. The humidity of 30%~70% RH is mainly to ensure that the ingredients maintain the best moisture. Moreover, no matter what the candy processing factory is in the production, processing, and storage of various hard candy, soft candy, chocolate, and chewing gum, the environment has a great impact on the quality, appearance, and taste of the finished product.

Moisture problems in the processing and packaging of confectionery products

Some typical moisture problems include blooming in chocolate. If chocolate absorbs moisture during packaging, the bloom is the crystallization of fat and sugar crystals. Moisture can also hinder natural flow because the material will stick to high-speed processing and packaging machinery, and it will stick to packaging materials. As a result, the processing speed becomes slower, and the moisture causes hygiene problems, resulting in production loss and lower quality of the final product.

During the manufacturing and coating process of candies (chocolate, candies, sweets), uncontrolled humidity/moisture can cause:

- The structure/size of the film core interface changes.

- Granular and irregular coating.

- Increase in residual moisture content and improper adhesion, that is, the degradation of coating quality in the presence of moisture.

- Sugar blooms and changes the flavor.

Therefore, candy factories need to closely control the environmental humidity during the production process to ensure that it will not be stuck during the packaging process. Generally, it is appropriate to control the humidity in the packaging workshop between 40% RH and 50% RH. In addition to packaging production, Storage must also do a good job of moisture control, which is very important to the quality of sugar food.

Moisture problems in candy storage

The two basic ingredients in candy, namely sucrose and corn syrup, are highly hygroscopic in nature, and when exposed to humid conditions, they can make the candy sticky, runny or moldy. Affect the storage life of candy.

Between manufacturing and consumption, most candies can be stored for about a week to a year. If stored under improper conditions, the candy will become stale and sticky over a longer period of time. The candy mustn’t lose its quality and flavor during storage. Since high temperatures will melt the product, any sugar-coated candy (such as chewing gum or chocolate-covered nuts) can benefit from using dry air to speed up the drying rate. By using a dehumidifier to dry air, candies or chocolates with a high gloss surface coating are obtained.

Sugary foods are very susceptible to moisture, and damp sugar foods are easily loved by various bacteria. Therefore, in sugar production enterprises, to ensure product quality, it is necessary to do a good job of preventing moisture.

Sugar food factories need to be equipped with dehumidifiers to prevent moisture and dehumidification, especially in the high temperature and high humidity season, it can ensure that the air humidity in the entire production process will not be higher than the production and storage requirements, and sugar food will not be damp, to ensure The smooth production in our workshop ensures the quality and storage safety of all kinds of confectionery products!

Alorair solution

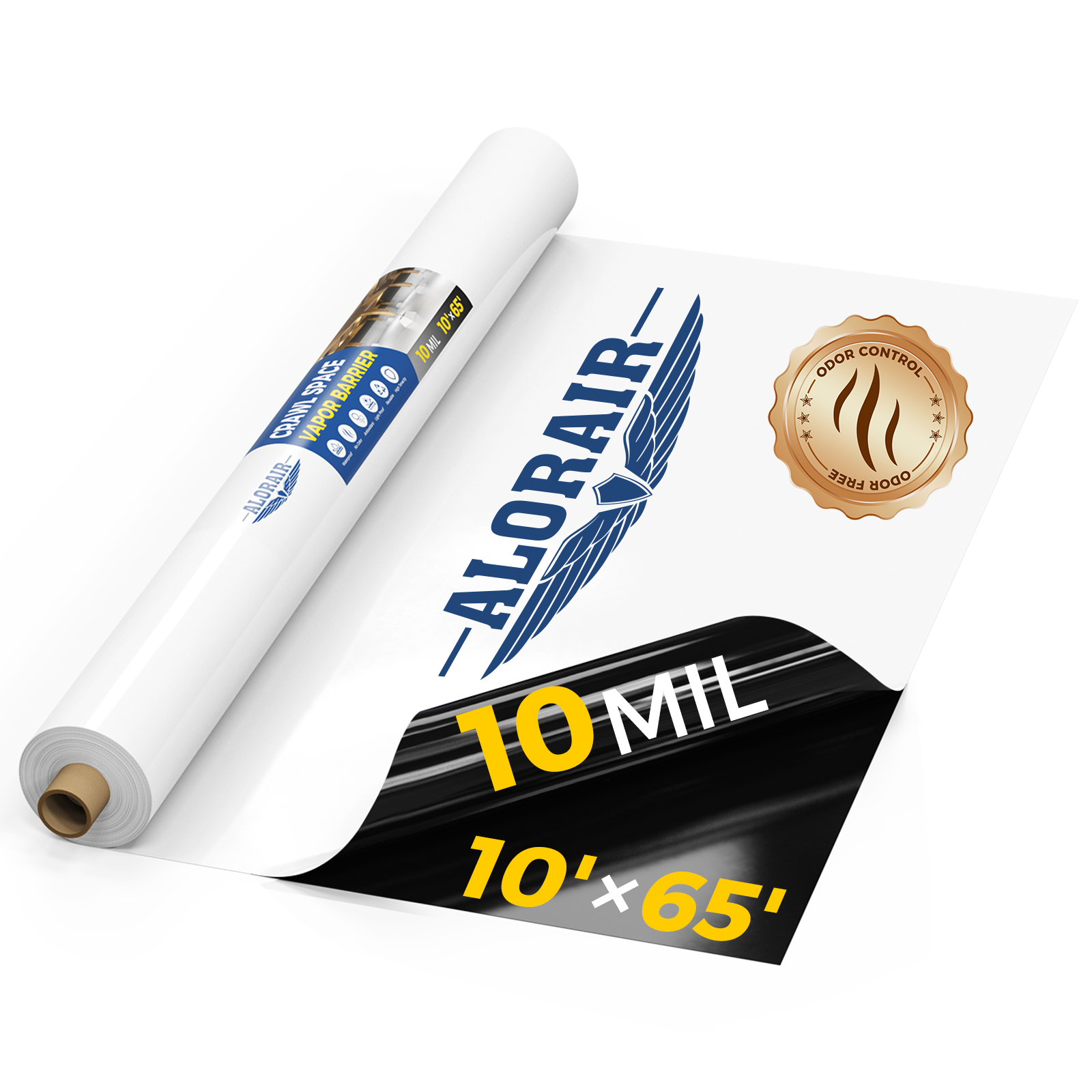

The solution lies in maintaining the required strict temperature and humidity conditions in the processing, packaging, and storage areas of dry air sweets and confectionery products.

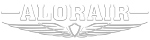

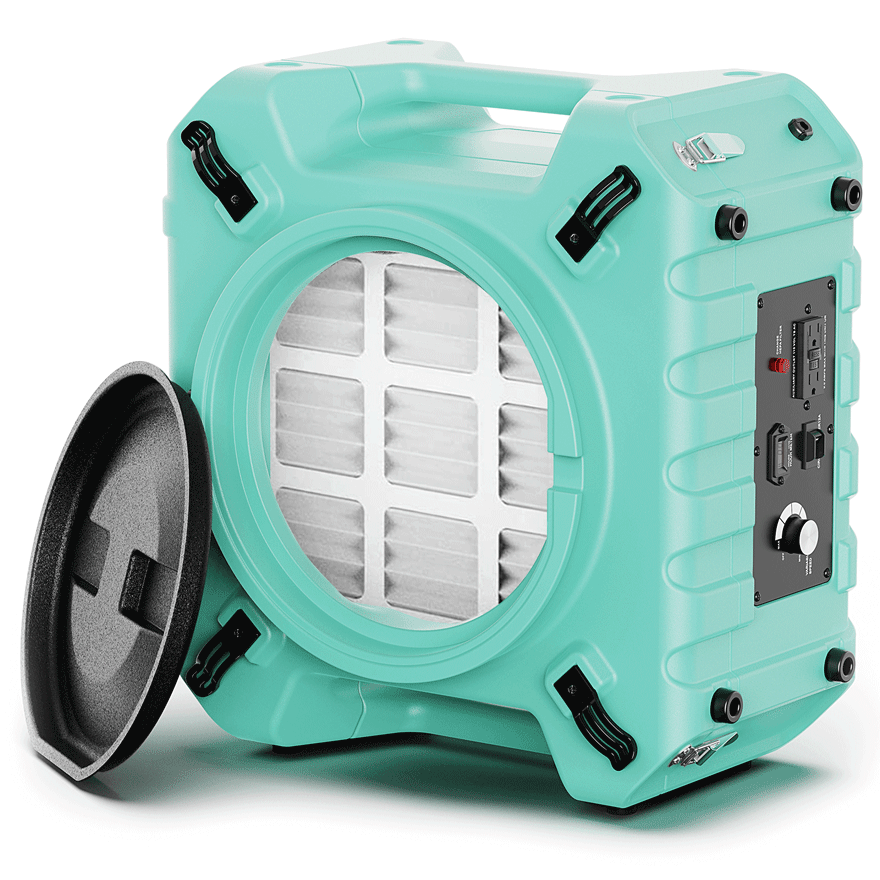

Alorair commercial dehumidifiers can reduce the moisture content of the surrounding air, are not affected by environmental conditions during production, storage, and packaging, maintain a constant RH level, help improve quality and keep chocolate and other sweets longer.

Correctly and reasonably use Alorair commercial dehumidifiers to dehumidify, and control the relative humidity of the workshop and warehouse environment below 50% RH, so that the candy factory can prevent the growth of bacteria and mold in the candy during the production and processing of various types of candy such as chocolate and chewing gum, and cool the candy. It can prevent condensation and prevent sugary ingredients from sticking together.

Choose the most effective dehumidifier that reduces humidity levels-shop here!

.jpg)

.jpg)

.jpg)

.HDi90.png)

.HD90.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-.jpg)

.jpg)

.jpg)

.jpg)

Exclusive offers

promotions

Exclusive offers

promotions