Are you suspecting that your house is becoming damp? It is normal. The day to day house chores such as cleaning and cooking, laundry and activities such as showering contribute to a significant increase in indoor moisture. While it is perfectly normal and explainable as to why your home is damp, the unpleasant environment created by excess moisture at home can be unsettling.

There are several possible ways in which you may reduce the moisture such as improving air circulation through ventilation or even using room heaters. Nonetheless, if you are not satisfied, you can choose to invest in a dehumidifier. These home devices are becoming commonplace in most homes, especially in regions where the atmospheric humidity is relatively high. They are designed to reduce air moisture to a specific percentage which is desirable and conducive for indoor environments. But how does a dehumidifier work?

Different dehumidifiers are designed with different operating mechanisms. However, the standard operational mechanisms include removing moisture by refrigeration and by adsorption.

Moisture Removal by Refrigeration

A refrigerant dehumidifier has the following as the primary components:

- Electric fan

- Compressor with coolants

- Cooling and reheating coils

- Drainage tank

When the device is connected to a power source and switched on, the fan is ignited. As it rotates, warm moist air is drawn inwards into the machine. The air passes through a set of filters where it is cleaned.

The sucked air is then channeled through a set of grills. The grills consist of pipes in which the refrigerant liquid passes. At this point, the refrigerant is in a liquid state, since it is compressed and is at a very low temperature.

As air passes over the pipes, the liquid refrigerant absorbs and cools the air below the dew point. As a result, the moisture held in the air mass condenses and trickles down to a drainage tank.

Since the air temperature will be significantly lower at this point, it is channeled to heating elements where its temperature is raised back to the original room temperature before being released.

During this process, there is an increase in the temperature of the refrigerant, which causes it to convert to a gaseous state. The gas is channeled to a compression chamber where it is cooled and compressed sufficiently to become a liquid, and the circulation process continues.

Meanwhile, as water accumulates on the drainage tank, its level is measured by a tipping bucket mechanism. When full, the sensors will send signals to the dehumidifier, and the user will see a blinking light which will make them aware that the bucket is full and needs emptying,

Moisture Removal by Adsorption

These dehumidifiers are packed with an adsorbent material (usually hydrophilic). A hydrophilic material is one that has a high affinity for water. When such materials are exposed to the atmosphere, they will absorb moisture which then causes them to change state.

Primary components of an adsorption dehumidifier

- Fan

- Rotor

- Heating elements

- Geared motors

It is also worth noting that all are fitted with filters to prevent any suspended particles from passing through the device.

At the heart of this dehumidifier is a rotor which is packed with an adsorbent material, most commonly, silica gel.

When the device is connected to a power source and switched on, the rotor ignites to motion and rotates slowly.

The fan begins rotating which draws in the air into the system. The warm moist air is filtered and channeled to the rotor. There, silica gel rapidly absorbs moisture from the air mass. Once the air has lost sufficient moisture, it is then channeled to the outlet.

During this process, the rate of absorption of moisture by the silica gel reduces gradually until it reaches a saturation point; where it cannot take in any more moisture.

At this point, the rotor transfers silica gel to the regeneration chamber. There, a separate mass of warm air passes over it causing it to lose moisture and become anhydrous again. Once this process is complete, the silica gel will be ready to absorb moisture from the air again.

The cycle is repeated. Since all the operational stages are self-reliant, there is little need for constant maintenance when it is in use.

Modifications in Working Mechanisms

Even though the two primary working mechanisms are by refrigeration and adsorption, there are many variations in the working mechanisms to increase efficiency.

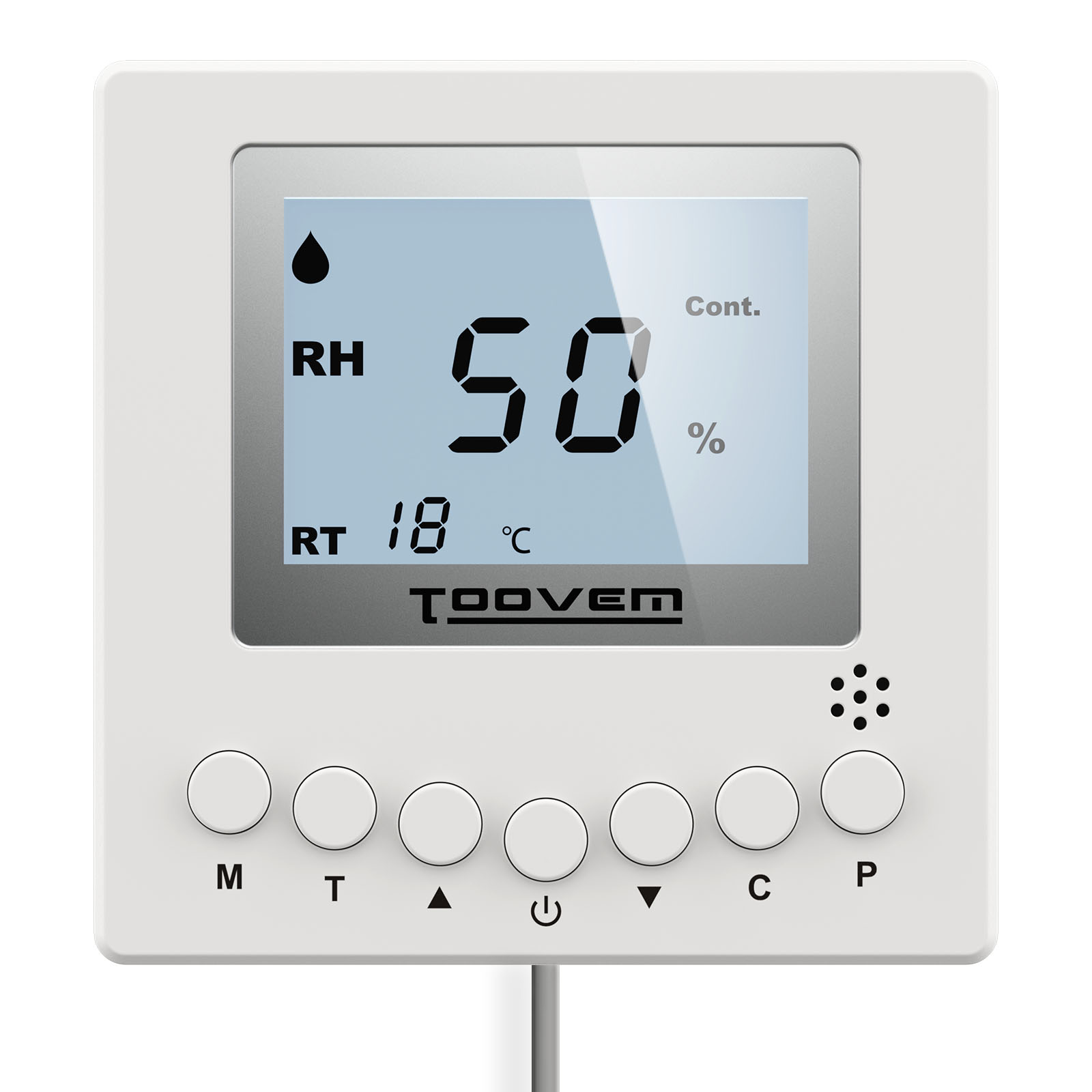

A classic example is the SLGR dehumidifier. In principle, it is a refrigerant dehumidifier. However, it has specialized technology and microchannels fitted into it which makes it efficient in water absorption. Additionally, it has a digital display function making it convenient for first-time users.

.jpg)

.jpg)

.jpg)

.HDi90.png)

.HD90.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-.jpg)

.jpg)

.jpg)

.jpg)

Exclusive offers

promotions

Exclusive offers

promotions