Clean air is important for everyone, whether you are at home or at a workshop. How the air you breathe makes you feel, how well you sleep, and how easy or hard it is to focus on day-to-day tasks. In most homes and workplaces, dust accumulates rapidly, the airflow is insufficient, and people experience more sneezing, coughing, or breathing disorders. The problems often arise from poor air circulation and also dirty air trapped indoors.

According to the U.S. Environmental Protection Agency, indoor air can be up to two to five times more polluted than outdoor air, particularly in enclosed areas such as residences and workshops. An air filtration system helps by sucking up dirty air, removing dust and small particles, and distributing cleaned air back into the space.

How to Boost Air Filtration System Efficiency

In this article, you will learn seven simple and proven tips that will help your air filtration system work better and help keep your air cleaner every day.

Tip 1 – Choose the right Air Filtration System for your space

Choosing the right air filtration system begins with understanding your space. A system that can be too small cannot clean the air quickly enough, allowing the dust to remain in the air for a longer period of time. This is a very common problem in garages and workshops.

A home air filtration system is typically set up for lighter dust and regular indoor air needs. In contrast, a workshop air filtration system will have to deal with heavier dust from tools and materials. So, if you want the dust to be filtered through multiple rooms in the house, a whole-home air filtration system may be a better option. Matching the system to the room size can help to improve the air flow and overall quality of the air.

As a general rule of thumb, small rooms, less than 800 sq. ft., typically require 500-800 CFM, medium-sized workshops between 800 and 1,100 sq. ft. fare best with 900-1,100 CFM, and larger or high-dust spaces may require 1,200 CFM or more. Matching the airflow capacity to the size of the room helps dust to clear more quickly and decrease filter strain.

Tip 2 – Change or Clean Filters Regularly

When filters get filled with dust, air will not be able to move freely through the air filtration system. This forces the system to work harder, which reduces the efficiency and leads to energy usage. Dirty filters also allow more dust to escape into the air again.

Filters should be checked on a regular basis, especially in areas with high dust. If air movement is weak or you find dust accumulating at a faster rate than normal, it is time to change or clean your filter.

Tip 3 – Enhance Airflow Around the System

Air vents and intakes should never be blocked. Furniture, boxes stacked on top of each other, or wood piles, for example, can prevent the air from circulating in a proper way, leading to a less effective system.

Wall-mounted and ceiling-mounted systems have different uses. Ceiling placement also tends to work best in workshops where fine dust remains suspended and circulates with airflow. Airflow direction is important since the clean air must be circulated to all areas of the room, and not only one corner. Good placement allows the air filtration system to clean better and faster.

Tip 4 – Controlling Dust at the Source

The fine dust particles are very light and can remain in the air for a long time. Activities such as sanding and cutting release dust that quickly flies around the room.

A dust collector provides an aid in the capturing of particles before they spread. In woodworking areas, a dust collector can be used together with a workshop air filtration system to lower the concentration of airborne dust. This combination enhances air quality and allows filters to stay cleaner for a longer period of time.

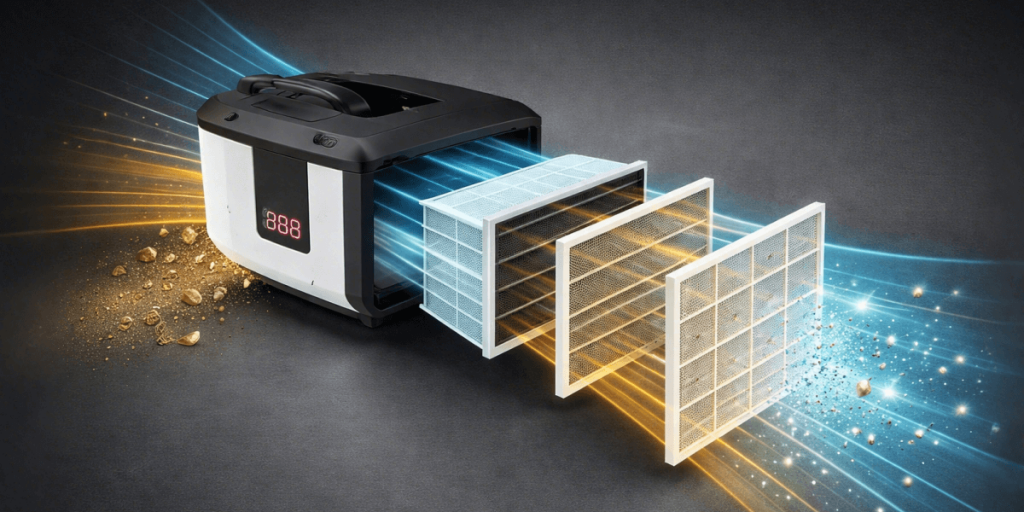

In active woodworking shops, the combination of a dust collector and a separate air filtration unit improves results. For medium-sized workshops, the AlorAir Purecare 780S has up to 780 CFM and a MERV 13 filter, making it effective against sanding and cutting dust that is left in the air after using machines.

Tip 5 – Make Use of the Right Fan Speed and Runtime

Short run times do not allow an air filtration system time to clean the air properly. Dust is suspended, particularly in busy work areas.

Running the system at the appropriate fan speed is a way to balance clean air and energy use. Higher speeds may be required for active work, while lower speeds can be used to sustain air quality later. Proper runtime helps improve performance without any wastage of power

Tip 6 – Maintain The Entire System, Not Just Filters

Dust may accumulate inside the fan and housing over time. This accumulation affects the airflow to make it less effective.

Loose seals and small gaps – these allow dirty air to escape before it is filtered. These leaks decrease system performance and waste energy. Keeping all parts clean and sealed helps the air filtration system to work at its best and last for a longer period of time.

Tip 7 – Upgrade When Your Needs Change

If you find that there is increasing dust, if you move to a new and larger space, or if you add new equipment, your existing system may not be able to keep pace. Newer systems are available with greater airflow, more powerful motors, and quieter operation. Upgrading to a larger or workshop unit can help greatly improve the air quality. A system that is designed to handle your current needs will be more efficient and provide you with greater results in the long run.

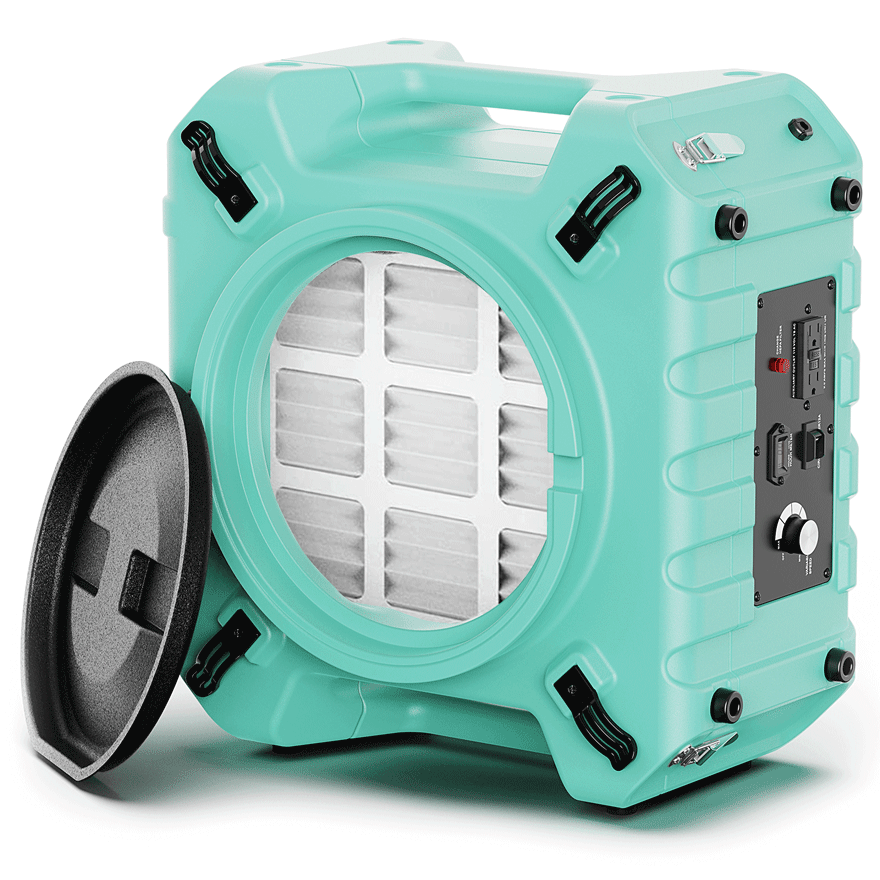

When the amount of dust increases or with the expansion of shop size, higher capacity systems are required. For larger workshops, the AlorAir Purecare 1050IG will provide up to 1050 CFM with double-sided air intake, which means it can clean air more quickly across wider areas. Its stainless-steel housing and durable design lend themselves to long work hours and heavier dust loads.

Choosing a Good Air Filtration Solution

Quality of Construction and Actual Performance

When selecting an air filtration system, build quality should be a high priority. There should be a combination of materials and construction in a well-made system to ensure it will perform well over time. Good air flow means that the system is able to draws in contaminated air and blow out the clean air equally throughout the space. Poorly constructed ones may lose efficiency at a very rapid rate and require frequent repair.

Significance of Industrial Grade Components

Industrial-grade parts are designed to run for long periods and withstand heavy dust without falling apart. These parts are particularly important in workshops and garages, where there is a larger amount of dust. Strong motors with sturdy housings can help ensure that there is a steady flow of air and that the system experiences less strain.

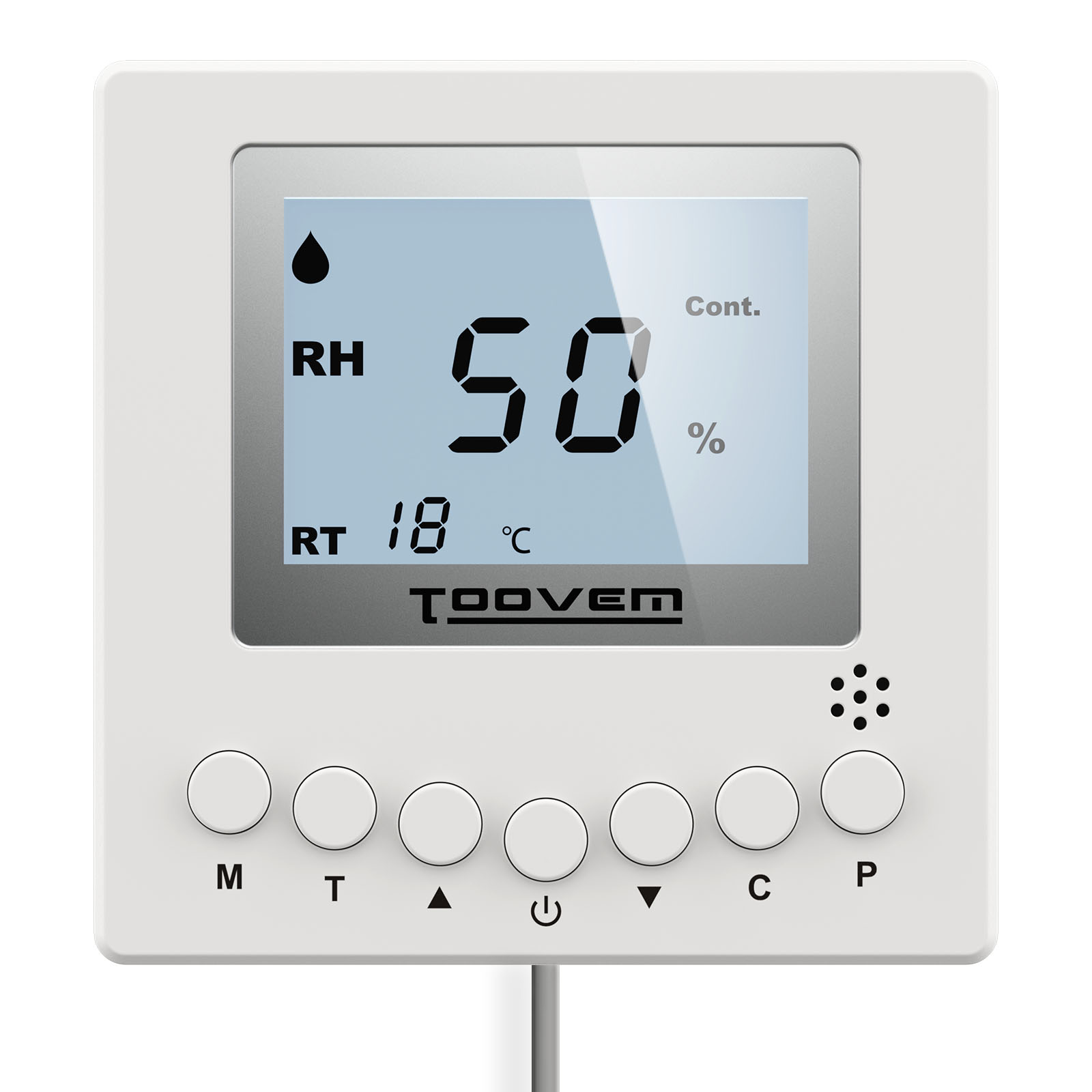

Moisture-Resistant and Professional Solutions

Moisture resistance has a very high importance in basements and in humid work areas, as moisture can damage the equipment and shorten its life.

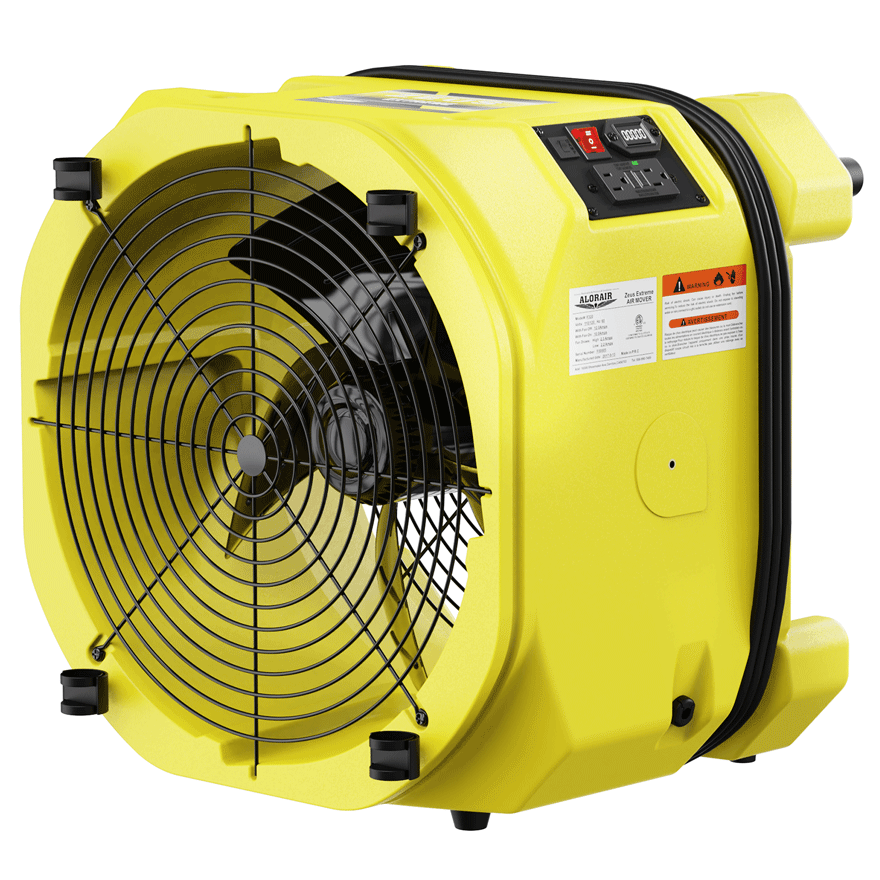

For demanding workshops and for long-term use, AlorAir air filtration systems are designed for use in rougher working environments and display consistent performance. Models such as the Purecare series are constructed with high airflow capacity, robust stainless-steel housings, and multi-stage filtration to handle the heavy-duty dust that is produced from woodworking, cutting, and sanding.

Features such as dual-speed fan, wide-angle air intake designs, low-noise operation, and optional ionization provide for quality air and comfort. These systems are ideal for garages, workshops, and industrial locations where reliability is an important factor.

Insider Knowledge and Industry Practice

Indoor air quality experts agree that proper filtration is an important component in the development of healthier spaces. The U.S. Environmental Protection Agency (EPA) states that good ventilation and good filtration help to reduce the airborne particles that can cause allergies and breathing problems. Industry organizations such as ASHRAE also suggest having properly sized filtration systems to provide better air flow and remove fine dust. These standards cover common standards for air movement, filter maintenance, and system room size.

For professional or high-dust environments, systems with wide-angle or full-circle air intake provide better coverage. Models like AlorAir Purecare 1350IG that have a 360-degree intake design and multiple MERV-11 filters are ideal for large woodworking shops where dust is being generated from more than one direction.

Breathe Better Air from Today!

Improving the efficiency of air filtration begins with the right system as well as smart daily habits. Matching airflow to shop size, controlling dust at the source, and keeping filters clean all make a noticeable difference. For woodworking environments, professional-grade systems are available – designed to handle heavier dust and longer run times. Explore proven and reliable woodshop air filtration systems to reduce airborne dust, protect tools, and keep your air cleaner and healthier for a safer workspace.

-(1).png)

.jpg)

.jpg)

.jpg)

.HDi90.png)

.HD90.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.webp)

.webp)

.webp)

.webp)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-.jpg)

.jpg)

.jpg)

.jpg)

Exclusive offers

promotions

Exclusive offers

promotions