What is Hygroscopicity?

Hygroscopicity describes how easily a substance will absorb moisture from the atmosphere. Sugar is hygroscopic because it readily absorbs water, and that is why sugar in the air can cause sugar syrup to solidify and sugar on a surface to crystallize. The main issue with sugar in the bakery is that it can cause the dough, or batter, to lose its elasticity and become brittle. This isn’t a problem limited to home bakers; even commercial bakeries have issues managing the humidity level of their products. Since we cannot control the weather, our only option is to work the amount of moisture in our bakery.

Bakeries within a climate-controlled environment have many options for keeping their products from getting too moist. When things get humid, they can turn on their air conditioning and dehumidifiers to decrease moisture levels. They also have ways to introduce dry air into their facilities and ensure that no air leaks out so they don’t lose control over humidity levels. There’s much less we can do in bakeries like ours, located outside of an urban area. We use fans, but they’re not very effective at moving large masses of humid air through the building; we need.

Effect of sugar’s high hygroscopicity

Sugar’s high hygroscopicity is a blessing and a curse in the bakery. On the one hand, it helps to improve the texture of bread and cakes that contain sugar. Sugars’ high affinity for water helps pull moisture out of the air and thus prevents the product from hardening prematurely. That said, this property can also make life difficult for the baker. Sugar absorbs water so quickly that any tiny amount of liquid contamination in a mix can throw off recipes and mixtures by 50% during storage. This can have disastrous results on flavor and texture if not caught early enough.

Ways to prevent products from absorbing moisture

As any food scientist who has ever worked with a highly hygroscopic substance can tell you, the amount of time you have to store your product before it breaks down depends significantly on how well you can control the moisture level within your storage environment. As sugars are very hygroscopic (they readily absorb moisture from their surroundings), every bakery should always be conscious of how much moisture is in their products’ air.

To prevent moisture from entering a product’s packaging, a baker must be aware of some of the most common methods used to help them maintain an appropriate storage environment:

It reduces the amount of open space in containers while increasing the surface area exposed to the air. This is accomplished through vacuum packaging, which involves placing a flexible plastic bag over a product and then using an external vacuum source (a specialized machine) to collapse the air between the two layers of plastic. By reducing the space between surfaces and forcing air out of that space, there is less moisture available for absorption.

Using desiccants to absorb stored moisture. Desiccants are materials that pull moisture from outside sources so that there is less available for other objects around them. Silica gel is one such desiccant,

Tips from bakers-how to improve productivity?

Aside from the evidence (hand-mixing instead of using a machine, wrapping sugar in several layers of plastic wrap, etc.), here are some things that have helped me prevent sugar from picking up moisture and turning into a sticky mess:

- Make sure your containers are as clean as possible. Sugar can cling to the tiniest bits of dirt.

- When you’re done working, wipe down your workstation with a damp paper towel to remove any stray sugar dust.

- When you’re done with an entire bag of sugar, tightly seal it in a container or plastic bag and place that container or bag in another container or bag filled with rice. The rice will absorb any excess moisture seeped into the bag or container during storage.

- If someone else is baking with sugar, let them know about the issues that can arise from its hygroscopicity and make sure they know what precautions to take to limit it.

Different group’s experiences on how to deal with it

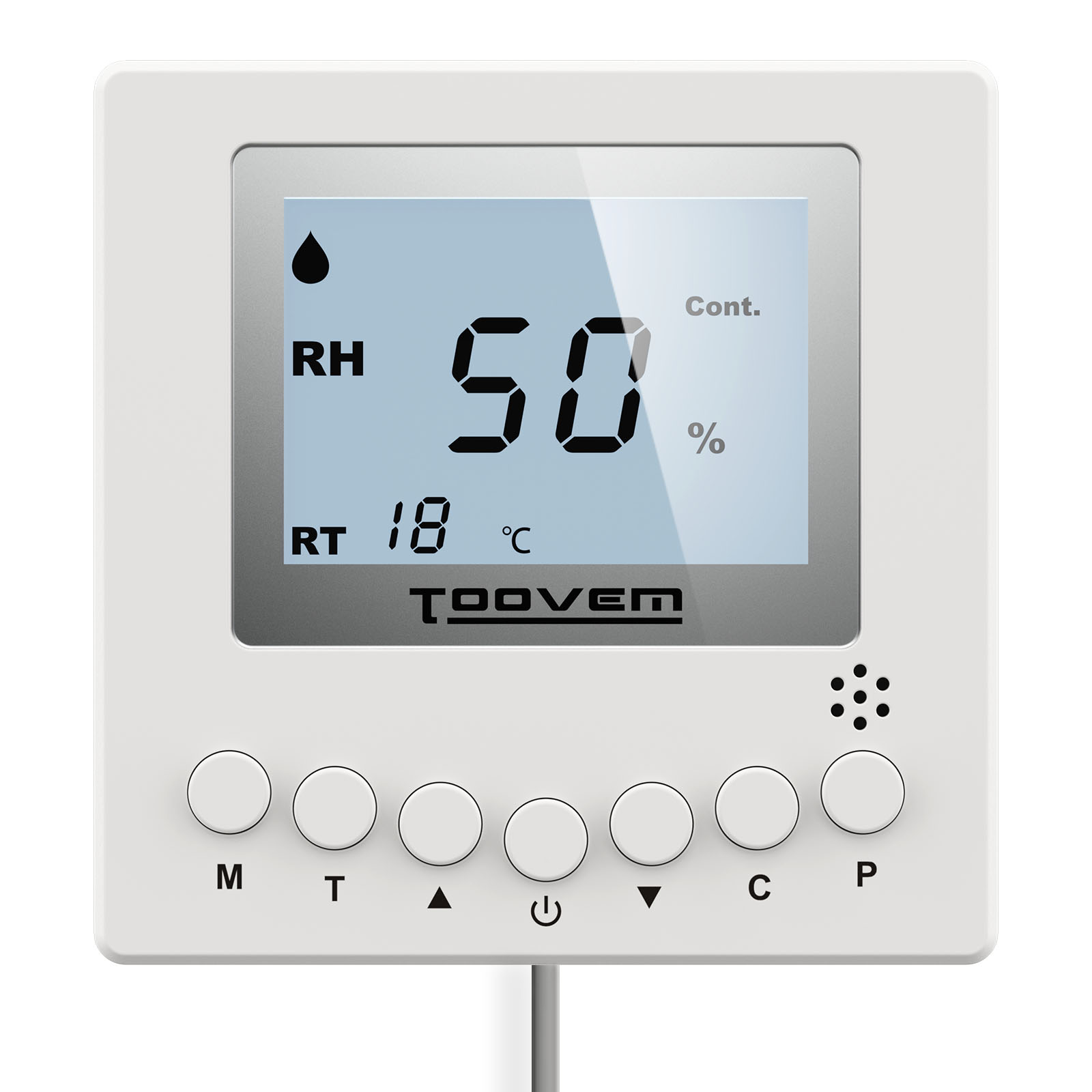

There are many different ways to cope with sucrose’s extreme hygroscopicity in the bakery. One of the easiest and most cost-effective methods is using a “dehumidification” technique. By fully closing our bakery for a few minutes every hour, we can reduce the humidity inside the building and keep it that way. This prevents sugar from absorbing any water vapor that would otherwise be present in the air. The only downside to this method is that it costs money—but it only needs to be done every hour, so costs are low.

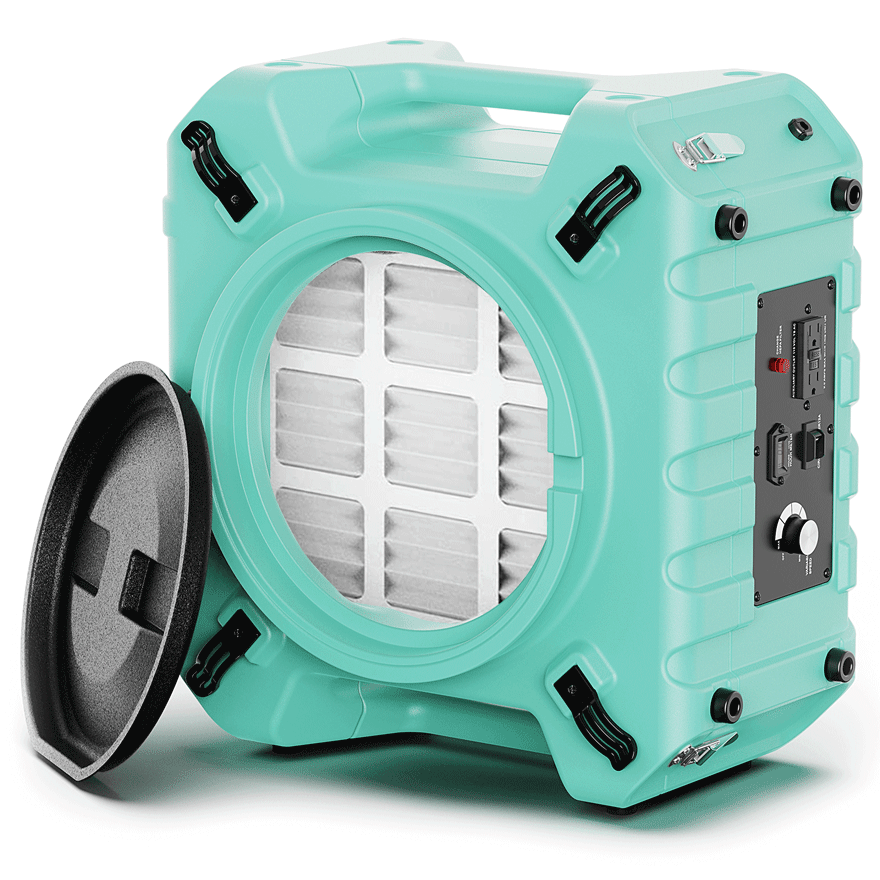

Another option is to use a “robotic dehumidifier”,which uses a fan to blow away excess water vapor, reducing the amount of moisture in the air. This method is also less expensive than dehumidification, but it has its drawbacks: it uses energy and can get loud. It also doesn’t work nearly as well—the fan on top of the building has to blow directly on all the surfaces you want to dry out (which can get complicated if there are multiple levels), and even then, it’s not nearly as effective as fully closing off an entire room.

Best recommendations:

The sugar industry has been using dehumidifiers for decades, and these machines have proven to be an integral part of their production processes. Dehumidifiers are used to dry out the moisture from the air, which changes its temperature and can cause problems for sensitive materials such as sugar.

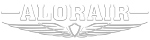

AlorAir Storm Extreme commercial-grade dehumidifier is a premium solution for your bakery’s needs. It is built to handle harsh conditions such as high humidity and condensation. The large two in. water pump removes about 5 gallons of moisture every hour, reducing the risk of mold and mildew growth. This bread-proofing dehumidifier also has a ProActive Alert feature that alerts you when you need to empty the bucket, so its operation is maintenance-free. For more information on any of our products, call us or visit us online at http://www.alorair.com/ .

.jpg)

.jpg)

.jpg)

.HDi90.png)

.HD90.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-.jpg)

.jpg)

.jpg)

.jpg)

Exclusive offers

promotions

Exclusive offers

promotions