Where you place your air filtration system is as important as the air filtration system itself. Good placement can help to remove dust, improve air circulation, and make the space safer to work in, while poor placement can result in dust build-up, poor airflow, increased tool wear, and constant carcinogen and expectorant breathing discomfort. In busy workshops, the presence of fine dust can remain in the air long after work has ceased, causing health and safety risks.

According to the U.S. National Institute for Occupational Safety and Health (NIOSH), workers are exposed to wood dust every year, which is associated with breathing problems and chronic health problems. An air filtration system operates by drawing in dirty air, trapping dust & particles, and releasing new air back into space. In this article, you’ll find out where to place a workshop air filtration system, how it works with a dust collector, and when a whole home air filtration system or home air filtration system makes sense.

Fine wood dust can remain intermittent for hours and is fine enough to be inhaled far down into the lungs. Without proper air filtration, enclosed woodshops can build up unsafe levels of dust very quickly, particularly when working on sanding and cutting.

Factors That Decide Best Place To Put A Shop Air Filtration System

Room Size and Layout

Room size directly affects the efficiency of the air filtration system. Larger spaces require stronger airflow, and ceiling height has an impact on the way dust rises and spreads. High ceilings also mean that dust will be in the room for a longer time, and so placement has to be taken into consideration regarding vertical air movement.

As a simple guide, for workshops less than 800 sq. ft., you require 500-800 CFM. Medium shops that range from 800 to 1,100 sq ft work best with 900 to 1,100 CFM. Larger or high-dust shops often require 1,200 CFM or more to keep the air clean.

Source of Dust

Dust is formed in areas where tools are being used the most. Sanders, saws, and planters emit small particles that disperse rapidly. The closer that system is to these work zones, the greater the potential for capturing dust before it is carried across the shop.

Airflow Patterns

Understanding how air moves through your shop is important. Air circulation should be free without being obstructed by walls, storage shelves, or stacked materials. Poor air circulation means poorer cleaning efficiency.

Noise, Power, and Safety

Always take noise levels, power access, and necessary safety clearance into account. Check local codes or shop rules to be sure that your installation complies with safety standards.

Best Spot for a Workshop Unit

Place the Unit Near the Dust Source

The workshop or best position for an air filtration system is as close to the source of dust production. Areas, such as sanding areas as well as main working benches, shed fine particles that remain in the air. Positioning the unit close by will enable it to collect dust before it is distributed throughout the shop, making the air cleaner more rapidly.

A dust collector removes the bigger chips and debris near the machines; however, that’s not the case with the fine dust. Having the air filtration unit in a close proximity to the same area of work can help catch these smaller particles. When both systems are used together, the airborne dust levels decrease, and filters last longer.

In open workshops, a unit centrally positioned in the room can clean the air for the entire room. This is a simple option that’s not as well-targeted. Multiple work zones with several smaller units near work zones give better control but need more planning.

Simple Placement Guide

- Unit place here – above the sanding area.

- Air intake – facing work zone.

- Exhaust – forcing clean air across the shop.

Ceiling-Mounted vs Wall-Mounted vs Floor Units

Ceiling-Mounted Units

Ceiling-mounted units are good because dust naturally moves up while the tools are running. Placing the unit overhead helps collect fine particles before they are distributed throughout the shop. These units are space-saving for floors and are ideal for constant airflow, especially in larger rooms. The height of the ceiling is important, though. Higher ceilings may require a higher air flow to efficiently clean the air.

Wall-Mounted Units

Wall-mounted systems are easier to access and filter changes and maintenance. They are best used in smaller shops with small paths of air movement and clear paths of air.

Floor Units

Floor units are portable and flexible, but can obstruct airflow if installed in the wrong location. Always leave open space around intakes and don’t place any unit near doors or windows that sweep dust inside the unit.

Positioning Units the Dust Source ( Using a Dust Collector)

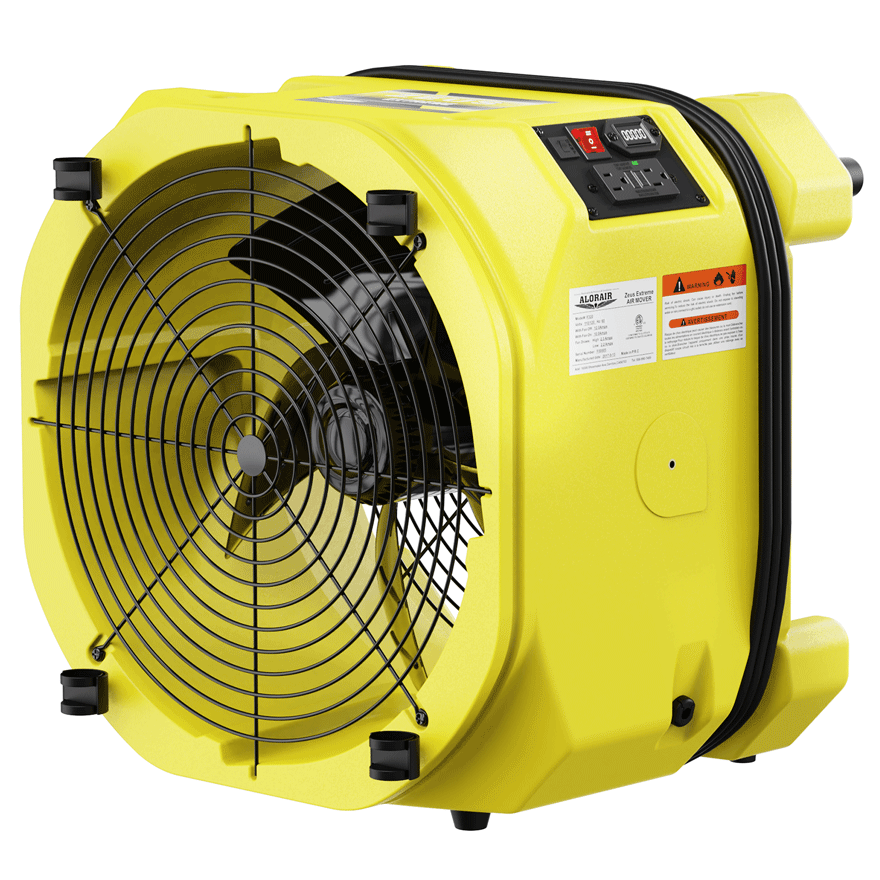

A dust collector is used to remove large chips and debris directly from machines, such as table saws and planers. However, there will often be fine dust escaping into the air. This is where an air filtration unit comes in.

Best Practice in Combined Use

The optimal configuration has the dust collector at the machine, and the filtration unit near the dust collector to catch what the collector does not. This layered approach minimizes airborne dust, keeping the shop cleaner.

Common Examples

To take an example, a table saw should be connected to a dust collector, whereas an overhead unit cleans the air in the surrounding environment. Sanding areas benefit from ceiling-mounted filtration, located just above the work zone.

Airflow and Circulation Rules

How Airflow Works

Airflow can be considered a simple route that air enters the system through the intake, runs through filters, and then exits as clean air. Proper circulation prevents the dust from settling in corners or dead zones.

Avoid Blocked Intakes

Never put the intake behind shelves, stacked materials, or equipment. Airflow being blocked reduces the cleaning efficiency and increases filter wear.

Improving Air Movement

If necessary, small fans or air movers can be used to assist with directing the flow of air toward the filtration unit. This is handy with long or narrow shops.

Testing Airflow Direction

A simple smoke or tissue test will illustrate the direction of airflow. Watch the movement of the air towards the intake.

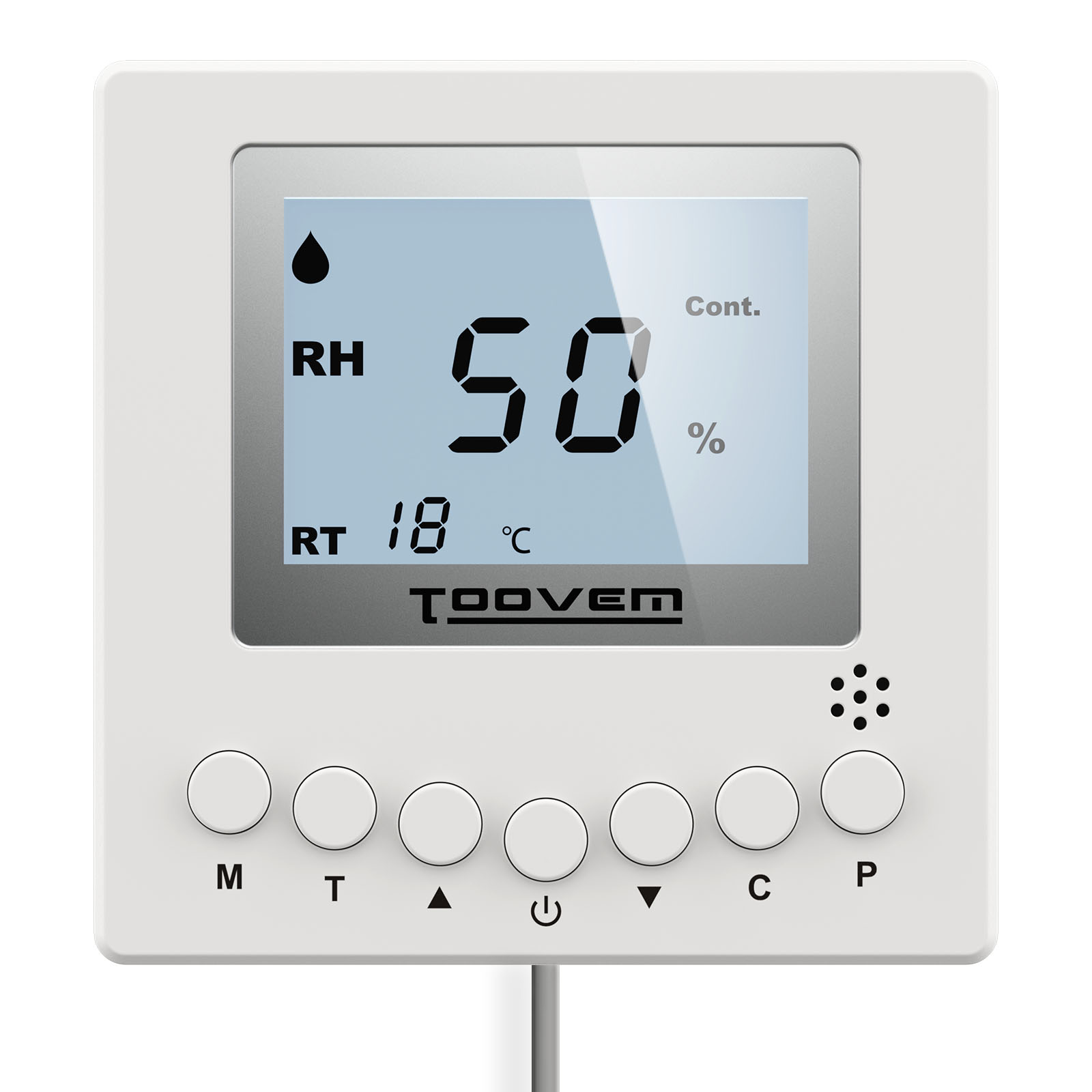

Match CFM to Room Size

For proper air turnover, always match the unit’s air flow rating to the size of the room.

Whole Home vs Single Workshop Unit

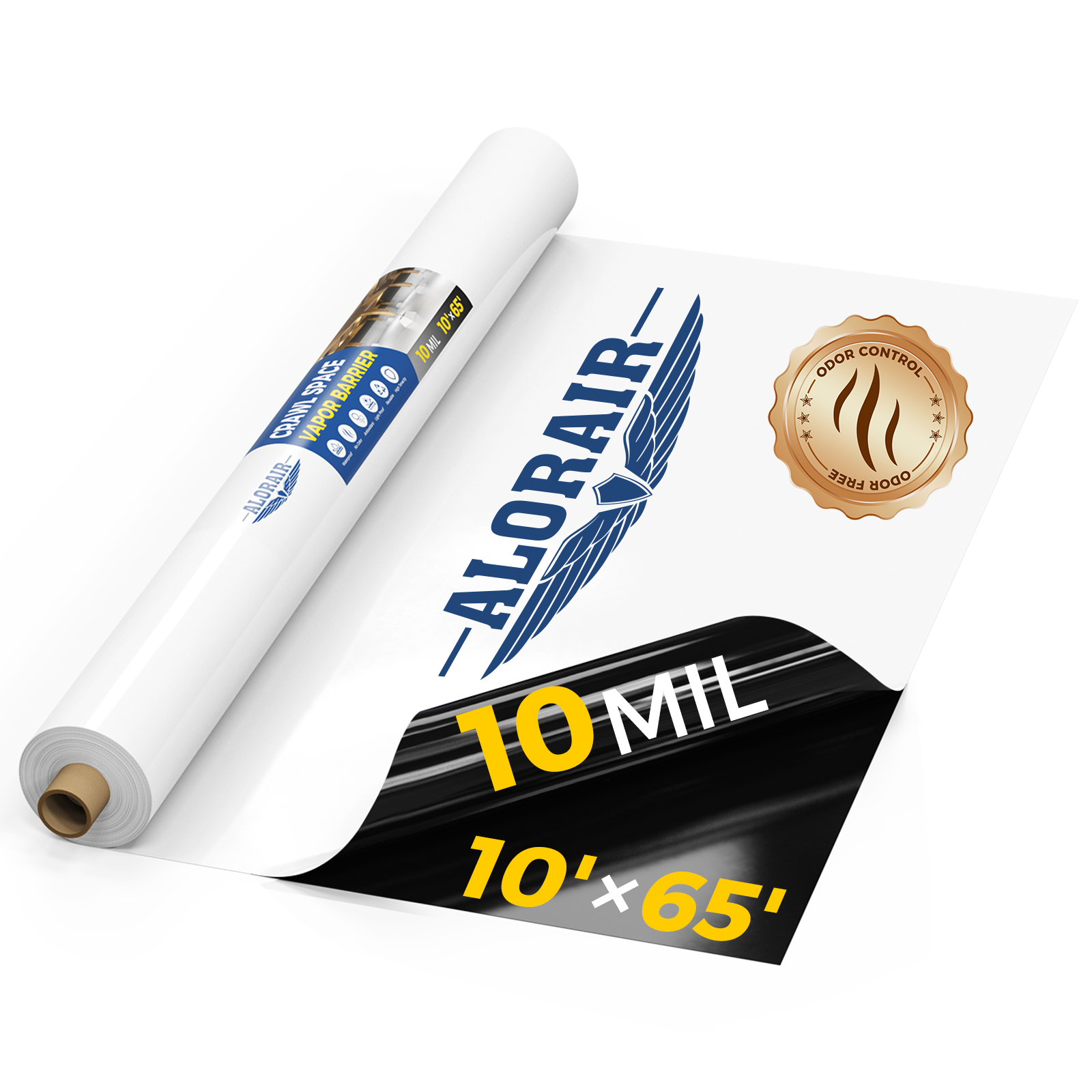

A whole-home air filtration system is handy when the dust blows from the shop to the living areas. This is common in attached garages or a basement workshop.

When a Shop-Only Unit Is Enough

A home air filtration system is usually sufficient for small and limited hobby shops where the amount of dust generated is limited.

Whole home systems will clean more than one room, but will cost more for installation. Shop-only units are units focused on one area and are more affordable. The choice that is made depends on how far the dust travels beyond the workshop.

Placement in Common Workshop Setups

Small Shops

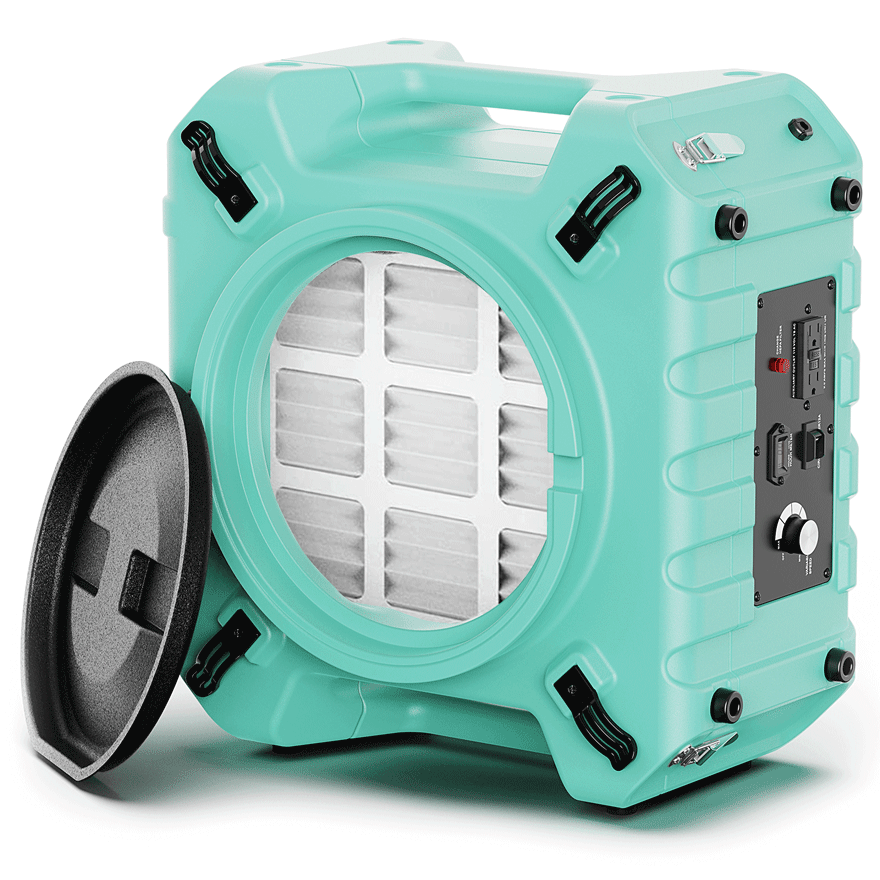

In one small shop, one unit positioned close to the main work area is usually sufficient. For small to medium workshops, the AlorAir Purecare 780S is good. It provides up to 780 CFM and is suitable for up to 800 sq ft spaces. Its small, suspended design conserves floor space, and the MERV-13 filter helps to trap fine dust from sanding and cutting. This model is very useful for home shops and for hobby woodworking.

Medium Shops

Medium-sized shops benefit from having one central ceiling unit or two wall-mounted units for better coverage. For larger workshops or larger dust levels, the AlorAir Purecare 1050IG is a stronger choice. With up to 1050 CFM, and a double-sided air intake, it allows it to clean air faster in wider spaces. The stainless-steel housing and built-in ionizer make it appropriate for frequent, long-hour use in active workshops.

Large or Commercial Shops

Larger shops may need more than one unit, ducting, or more than one dust collector to handle heavy dust loads. For professional or high-dust environments, the models have maximum coverage, like the AlorAir Purecare 1350IG. Its 360-degree intake design and multiple MERV-11 filters are designed to pick up airborne dust from all angles, which makes it perfect to use in a large woodworking shop or commercial space.

Easy Maintenance & Placement Testing

How Location Impacts Maintenance

Units located near sources of heavy dust may require filter replacement on a more frequent basis. This is normal, but it is something that should be planned for.

Quick Performance Checks

Regularly check filters, touch the strength of the air, and conduct a smoke or tissue test to confirm proper circulation.

When to Reposition the Unit

If you notice an accumulation of dust is occurring repeatedly, there are new machines, or there is a change in the shop layout, move the unit to ensure better coverage.

Routine Checkup

Recheck placement every three to six months to be sure the system still meets your needs.

Choosing the Right System & Getting Started

A high-quality workshop air filtration system should be constructed that can run for many hours and handle heavy dust without failures. Look for strong airflow, durable construction, and wide-angle intake designs. Professionally designed systems work better in demanding spaces.

AlorAir models are designed for harsh environments and are geared towards dependable dust control with a dust collector. These types of solutions are excellent as a stand-alone air filtration system for workshops and can also supplement a home air filtration system or whole home air filtration system when dust spreads outside of the shop.

The best placement captures dust early, matches air movement to room size, and is easily adjusted over time. Small changes in position can help greatly in results. Compare workshop models, select the right size, and site your system smart. Proper positioning is a great time-saving and health-saving measure, as well as keeping tools and workspaces cleaner each and every day.

-(1).png)

.jpg)

.jpg)

.jpg)

.HDi90.png)

.HD90.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.webp)

.webp)

.webp)

.webp)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-.jpg)

.jpg)

.jpg)

.jpg)

Exclusive offers

promotions

Exclusive offers

promotions