In the brewing workshop of the winery, due to the large amount of water used in the brewing process and the many cooking or cooling processes, the heat and moisture load of the entire brewing workshop is very large, and condensed water is often formed on the ceiling or roof.

The presence of condensed water provides conditions for the reproduction of molds and other microorganisms, which can easily cause mold on the ceiling or roof. Once the condensation drips, whether it drips into the brewing workers, brewing equipment, or brewed wine, it will cause indirect or direct pollution and affect the health and safety of winemaking.

In the brewing process of some wineries, a large amount of moisture-containing water vapor volatilizes and diffuses in the closed and air-tight workshop, causing smoke in the workshop, low air visibility, slippery ground, and dirty air. It can affect the normal production and operation order of the workshop, the health, and safety of products, the service life of machinery and equipment, etc., and seriously endanger the health of employees and cause occupational diseases. In this case, the water vapor in the workshop must be treated. Quickly remove, reduce the content of water vapor in the workshop.

So, how to quickly and completely solve the water vapor in the brewing workshop?

The main reason for the condensed water produced in the brewing workshop of the winery is that on the one hand, the overall workshop environment has always been relatively humid. On the other hand, a large amount of water used in the brewing process, and the large amount of steam generated during the cooking or cooling process. A humid environment is often unavoidable for wineries, especially for roasting wine. Hot gas resources are leaked into the environment when brewing and cooking equipment is in the cooking operation. Nevertheless, reducing the area of the environment with the water surface, optimizing the operation of cooking equipment, and reducing the leakage of hot air can greatly reduce the condensate load of the workshop.

Someone proposed to make the ceiling of the workshop curved or inclined, the purpose is that the condensed water can flow along the inclined or curved surface and drain to the water tank after condensation. This method is not feasible because the height of the workshop is limited, which cannot meet the slope of the slope to prevent dripping.

Increasing ventilation in the workshop can greatly reduce the humidity of the environment in the workshop, thus significantly reducing the condensation load of the workshop. However, while increasing the ventilation, dust, and microorganisms in the outdoor environment will also enter the wine workshop, which will bring new health threats.

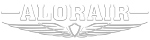

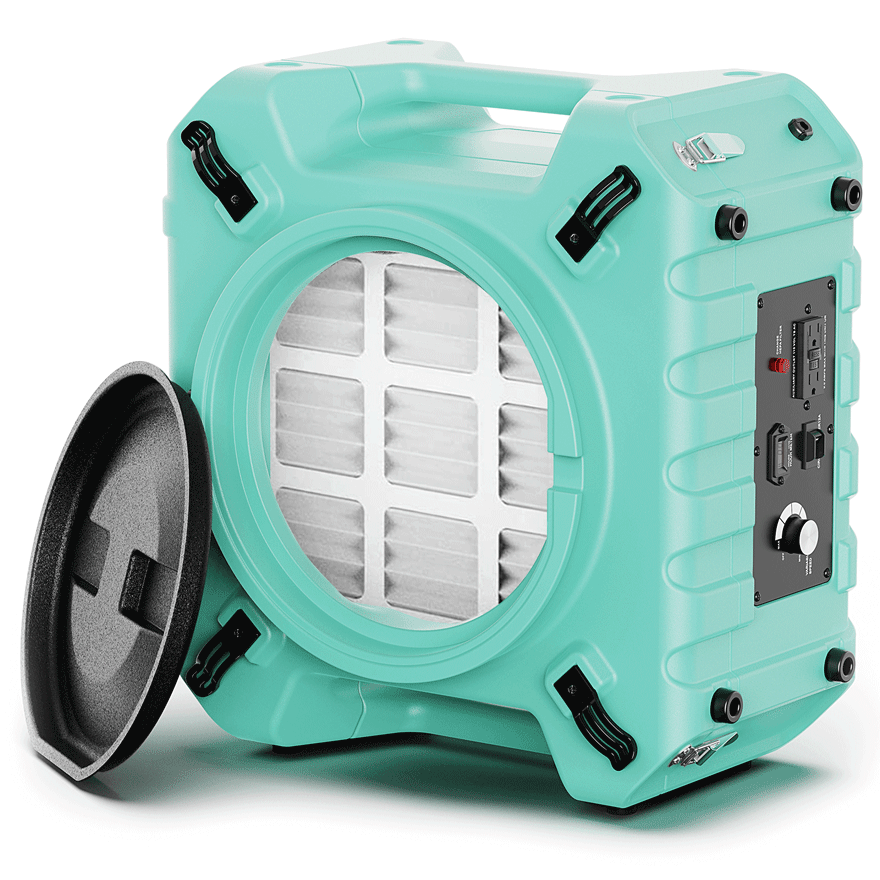

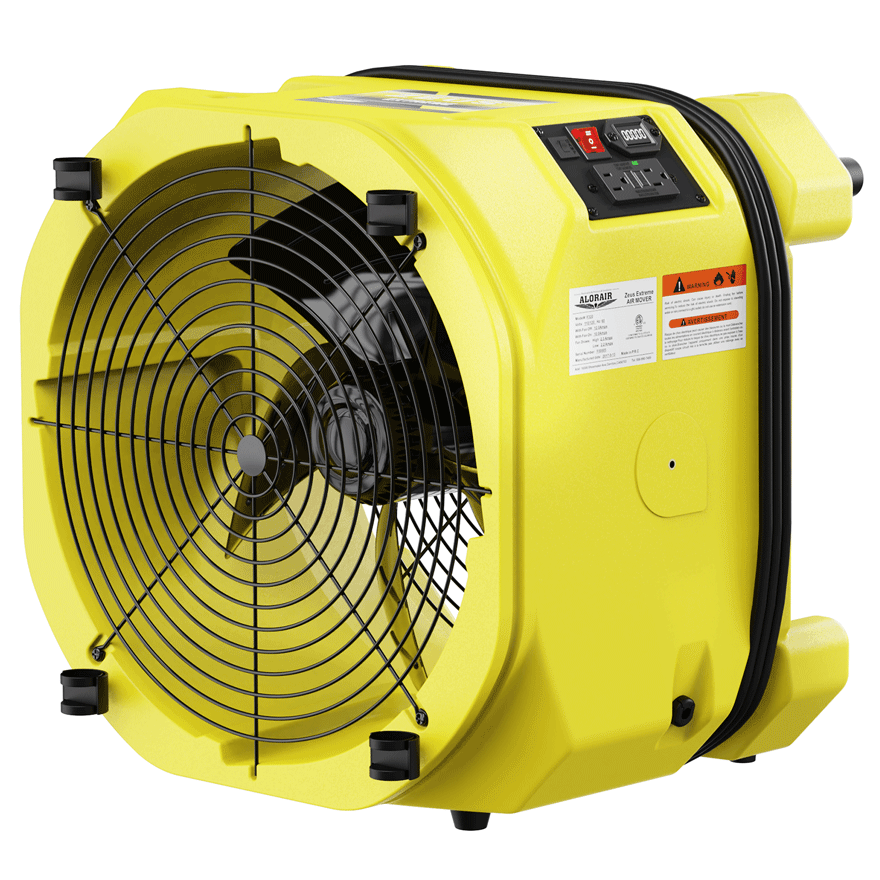

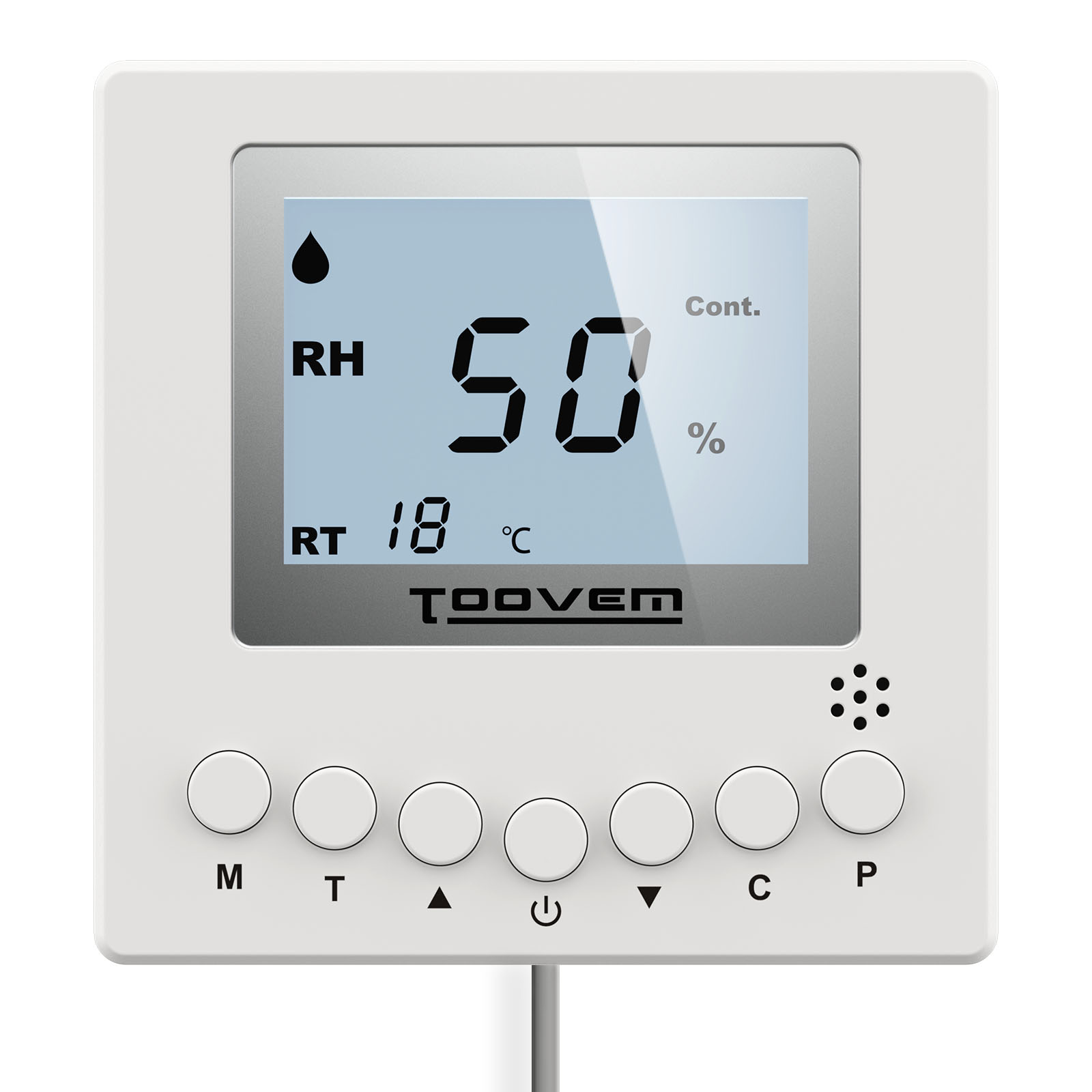

The most effective method is to use dehumidification equipment. Alorair commercial dehumidifier is an efficient, energy-saving, and environmentally friendly dehumidification product manufactured by strictly using professional technology and exquisite craftsmanship. It has an intelligent constant humidity control system. Users can automatically control the work and shutdown of the dehumidifier according to the needs of production. Automatic control realizes the high-efficiency dehumidification effect and reduces the operating cost of the whole machine.

Most of the brewing workshops will produce a large amount of steam during the roasting or cooking process. The continuous accumulation of large amounts of steam will seriously interfere with and affect the ground environment and the normal work of personnel. Especially in the cold winter, the temperature difference between indoor and outdoor is large. A large amount of steam in the workshop will be on the top of the workshop when encountering cold air. The surface of machinery and equipment or walls will condense into water droplets, which will seriously affect the normal production and products of the workshop. Quality. Therefore, these wineries or enterprises must solve the problems of excessive steam in the workshop, condensation on the ceiling, or condensation in the cold winter.

Properly and reasonably use Alorair commercial dehumidifiers to dry the steam-rich air in the entire brewing workshop or local areas. When the dehumidification capacity is configured sufficiently, the effect of removing steam and moisture is very obvious.

When choosing a commercial dehumidifier, the factory or enterprise user should remember that the larger the dehumidification capacity, the better, but should choose according to their own needs and the area used. Commercial dehumidifiers produced by Alorair have a variety of models with different capacities. You can choose the model that suits you, which not only guarantees an effective dehumidification effect but also provides quality service and after-sales guarantee.

To get the most efficient and durable commercial dehumidifier-shop here!

.jpg)

.jpg)

.jpg)

.HDi90.png)

.HD90.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-.jpg)

.jpg)

.jpg)

.jpg)

Exclusive offers

promotions

Exclusive offers

promotions