Wood dust is a byproduct or waste product of woodworking operations such as sawing, sanding, milling, planing, and routing. It consists of small sawdust, the residue from saw teeth when the wood is processed into lumber, and its production can cause a number of problems for humans.

The dangers posed by sawdust

1. Health hazards

Employees who work with wood are at risk of inhaling fine wood dust. Breathing dust on the job can damage the lungs, which over time can lead to respiratory diseases such as chronic obstructive pulmonary disease (COPD) and occupational asthma. Carpenters and joiners are four times more likely to develop asthma than other workers. Deposited dust contains the finer particles most likely to damage the lungs. Hardwoods such as oak, western red cedar, and iroko are carcinogens and can lead to sinus cancer.

2. Fire and explosion hazards

If part of a sawdust cloud is ignited and the flames spread to the rest of the cloud, the sawdust can explode. Not all combustible dusts are equally explosive and may explode to different degrees.

3. The impact of sawdust on environmental pollution

The sawdust and dust generated from cutting wood boards have unintended effects on environmental pollution. At the same time, the sawdust has a significant impact on the total phosphorus and ammonia nitrogen COD (chemical oxygen demand) in water bodies, which leads to the deterioration of the water environment.

The role of the dust collector

Dust collectors are important devices used in many industries and businesses. They play a key role in dealing with dust particles and preventing them from polluting the air and posing a health risk to employees, customers and the public. The main purpose of a dust collector is to capture airborne dust before it becomes airborne and pollutes indoor air.

The main advantages of the AlorAir dust collector:

1. Built-in ion generator

The maximum power of the ion generator can reach 15 million negative ions/second and 10 million positive ions/second, which effectively increases the air purification effect and is suitable for wood carving, grinding, turning, fretwork, powder mixing and so on.

2. Innovative four-sided surround filter system

This air filter system comes with 2 filters, both of which can be easily replaced and reused. The outer filter removes larger particles and the inner filter captures smaller particles.

3. Remote control

This dust collector is easy to mount on a workbench or other dust generating work surface (convenient carrying handle for easy mobility and rubber feet to protect from damage). An integrated RF remote control allows operation from any angle in the room.

4. Various sizes are available

Types and sizes are complete, and you can choose dust collectors of different types and sizes according to your needs.

5. Easy installation, simple operation and low maintenance costs

The PuriCare 1100IG filtration system comes pre-assembled, so all you have to do is decide where to place the unit. Be sure to check out our instruction manual. It’s easy to use and doesn’t require much time to learn. As for maintenance, the system doesn’t require much attention other than the occasional filter change and weekly cleaning

Our recommendation:

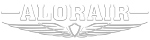

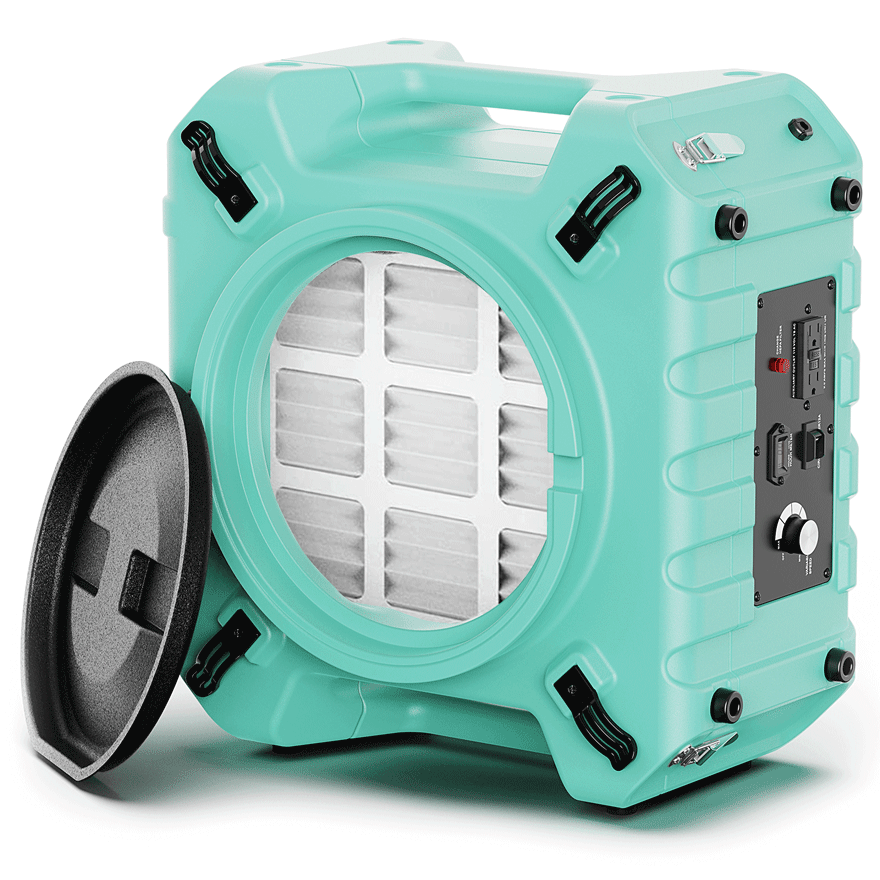

Air filtration system

Puricare 500

Small room size (≤ 500 sq.ft)

Airflow: 500 CFM

Remote control: Yes

Air filtration system

Puricare 500IG (Built-in ion generator)

For Small room size (≤ 500 sq.ft)

Airflow: 500 CFM

Remote control: Yes

Air filtration system

Puricare 1100

For Small room size (500-1000 sq.ft)

Airflow: 500 CFM

Remote control: Yes

Air filtration system

Puricare 1100IG (Built-in ion generator)

For Small room size (500-1000 sq.ft)

Airflow: 500 CFM

Remote control: Yes

Air filtration system

Purecare 1350

For Small room size ( ≥1300 sq.ft)

Airflow: 1350 CFM

Remote control: Yes

Air filtration system

Purecare 1350IG (Built-in ion generator)

For Small room size ( ≥1300 sq.ft)

Airflow: 1350 CFM

Remote control: Yes

Other suggestions:

√ Use exhaust from saws and sanders to control wood French fries at the source.

√ Don’t use blowers, fans, or compressed air to move wood French fries.

√ Avoid the risk by purchasing pre-cut or processed wood.

√ Workers are advised to wear respiratory protective equipment (PPE) when emptying vacuum

√ bags or collection bags, as they may be exposed to large quantities of wood French fries.

√ Instruct employees to wash their hands and face immediately after work and before eating, drinking, or smoking.

.jpg)

.jpg)

.jpg)

.jpg)

.HDi90.png)

.HD90.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-.jpg)

.jpg)

.jpg)

.jpg)

Exclusive offers

promotions

Exclusive offers

promotions